Model |

FLS-400-220 |

Supply Voltage |

380 Volt, 50 Hz |

Installed Power |

6000 Watt |

Average Consumption |

4800 Watt |

Maximum Product Width |

350 mm |

Maximum Product Height |

200 mm |

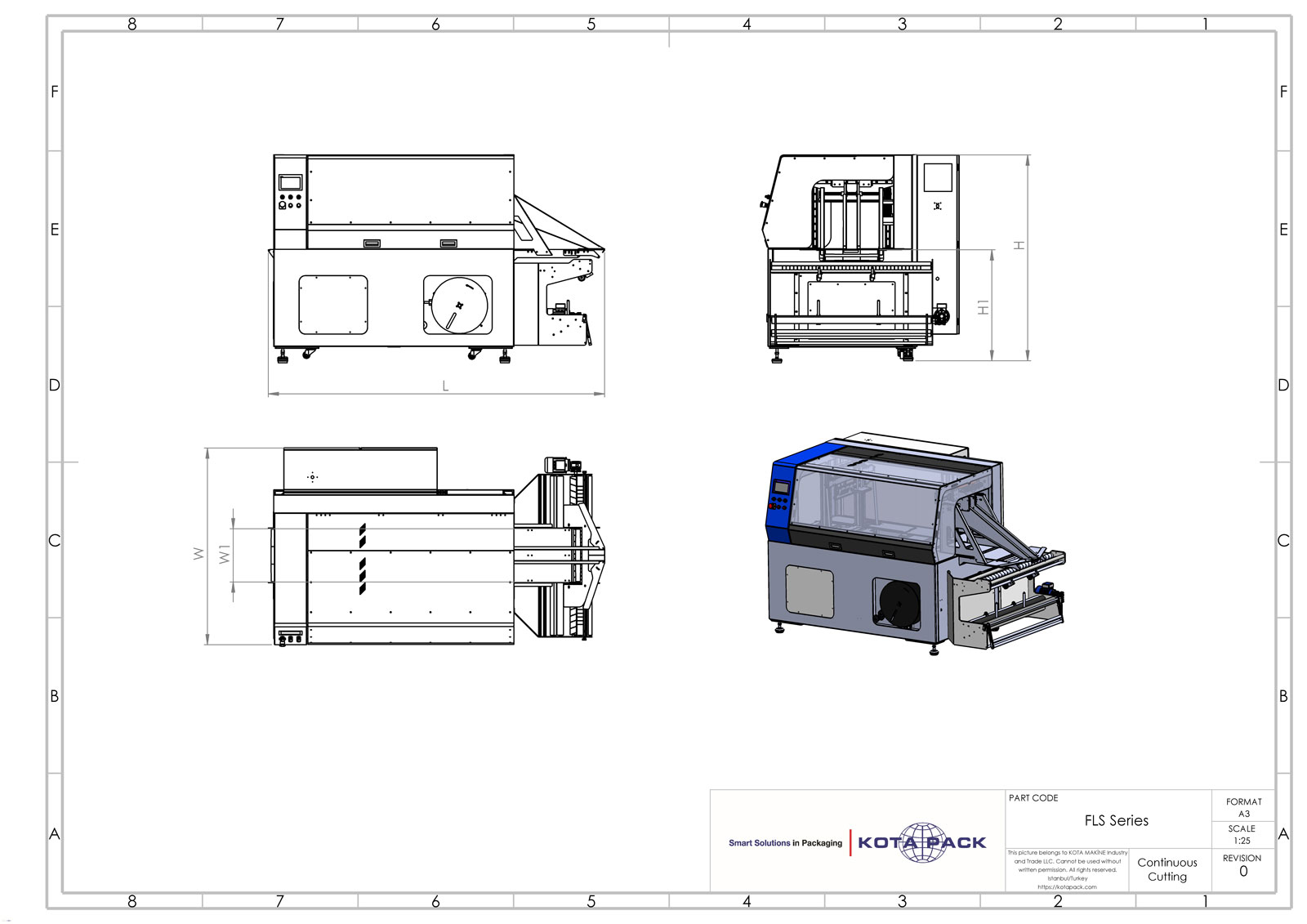

Conveyor Belt Width (W1) |

405 mm |

Sealing Bar Length |

520 mm |

Maximum Film Dimensions |

Ø350-850 mm |

Working Height (H1) |

850 mm (+50) |

Machine Dimensions (L x W) |

2660 x 1580 |

H 1500 mm |

|

Machine Weight |

1010 Kg |

Available Films |

PE-POF: 7-80 µ |

Air pressure |

6 Bar |

Maximum Conveyor Speed |

37 m/min |

Maximum Capacity |

90 pcs/min |

Model |

FLS-400-320 |

Supply Voltage |

380 Volt, 50 Hz |

Installed Power |

6000 Watt |

Average Consumption |

4800 Watt |

Maximum Product Width |

350 mm |

Maximum Product Height |

270 mm |

Conveyor Belt Width (W1) |

405 mm |

Sealing Bar Length |

520 mm |

Maximum Film Dimensions |

Ø350-1050 mm |

Working Height (H1) |

850 mm (+50) |

Machine Dimensions (L x W) |

2660 x 1580 |

H 1500 mm |

|

Machine Weight |

1300 Kg |

Available Films |

PE-POF: 7-80 µ |

Air pressure |

6 Bar |

Maximum Conveyor Speed |

37 m/min |

Maximum Capacity |

90 pcs/min |

Model |

FLS-400-370 |

Supply Voltage |

380 Volt, 50 Hz |

Installed Power |

6000 Watt |

Average Consumption |

4800 Watt |

Maximum Product Width |

350 mm |

Maximum Product Height |

300 mm |

Conveyor Belt Width (W1) |

405 mm |

Sealing Bar Length |

520 mm |

Maximum Film Dimensions |

Ø350-1200 mm |

Working Height (H1) |

850 mm (+50) |

Machine Dimensions (L x W) |

2660 x 1580 |

H 1600 mm |

|

Machine Weight |

1400 Kg |

Available Films |

PE-POF: 7-80 µ |

Air pressure |

6 Bar |

Maximum Conveyor Speed |

37 m/min |

Maximum Capacity |

90 pcs/min |