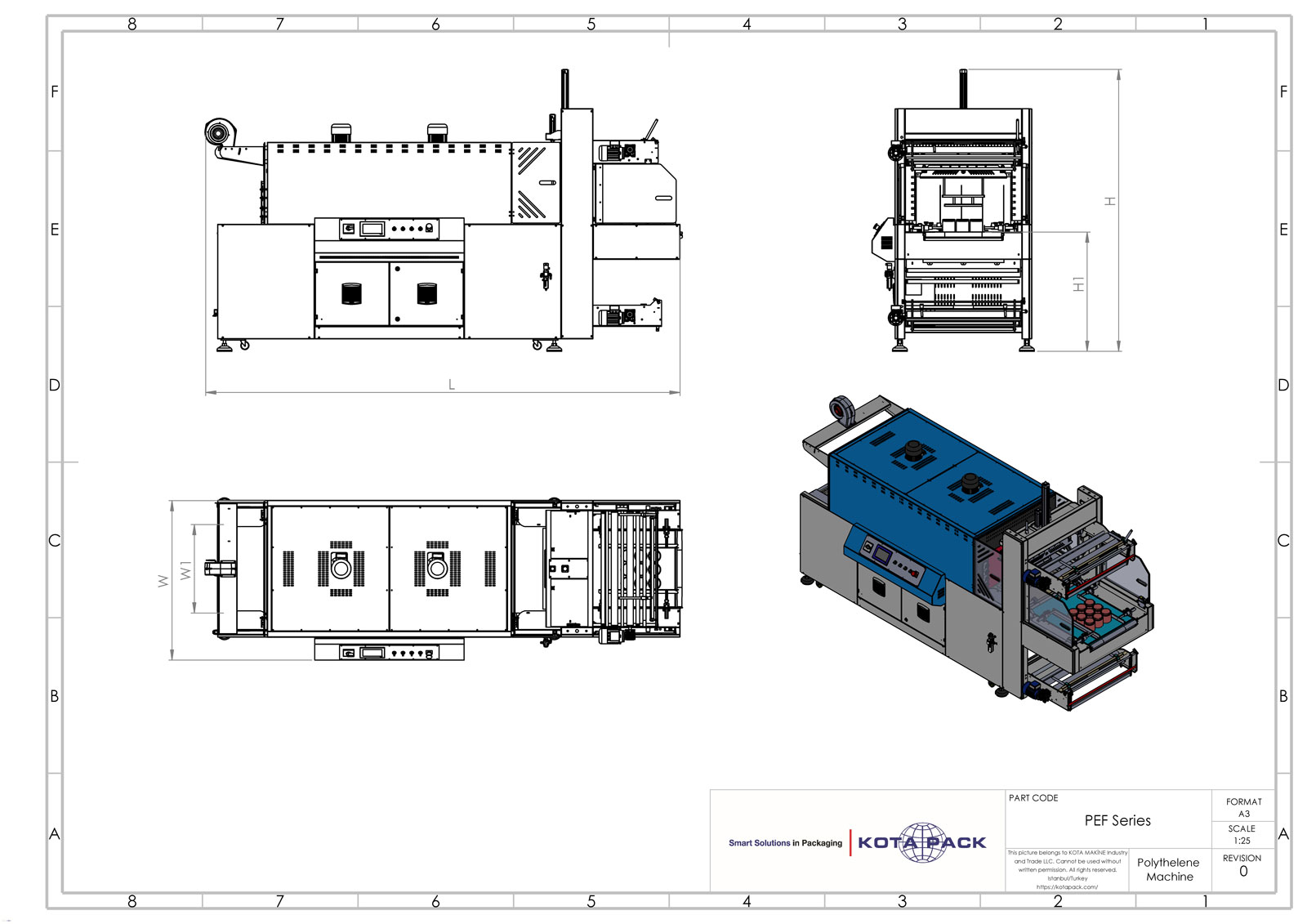

Model |

PEF-6545-F2 |

Supply Voltage |

380 Volt, 50 Hz |

Installed Power |

26000 Watt |

Average Consumption |

20800 Watt |

Maximum Product Width |

620 mm |

Maximum Product Height |

400 mm |

Conveyor Belt Width (W1) |

710 mm |

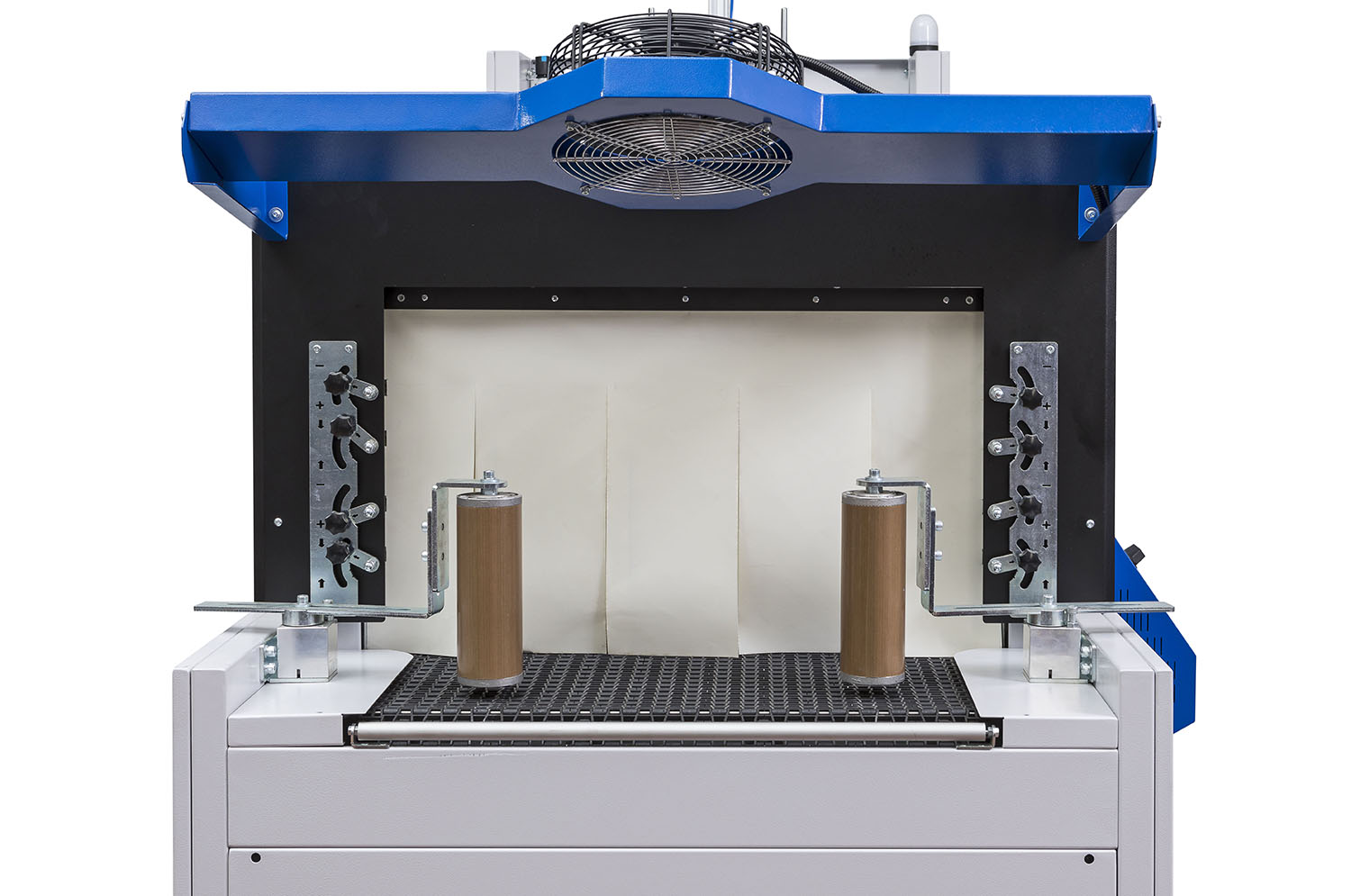

Sealing Bar Length |

670 mm |

Maximum Film Dimensions |

Ø350-650 mm |

Working Height (H1) |

950 mm (+50) |

Machine Dimensions (L x W) |

3800 x 1300 |

H 2250 mm (+50) |

|

Machine Weight |

950 Kg |

Available Films |

PE: 15-100 µ |

Air Pressure |

6 Bar |

Required Air |

13 Nl/p |

Maximum Conveyor Speed |

m/min |

Maximum Capacity |

20 pcs/min |

Supply Voltage

Model |

PEF-8545-F2 |

Supply Voltage |

380 Volt, 50 Hz |

Installed Power |

26000 Watt |

Average Consumption |

20800 Watt |

Maximum Product Width |

820 mm |

Maximum Product Height |

400 mm |

Conveyor Belt Width (W1) |

910 mm |

Sealing Bar Length |

870 mm |

Maximum Film Dimensions |

Ø350-850 mm |

Working Height (H1) |

950 mm (+50) |

Machine Dimensions (L x W) |

3800 x 1500 |

H 2250 mm (+50) |

|

Machine Weight |

1055 Kg |

Available Films |

PE: 15-100 µ |

Air Pressure |

6 Bar |

Required Air |

13 Nl/p |

Maximum Conveyor Speed |

m/min |

Maximum Capacity |

20 pcs/min |

Supply Voltage