Model | PER-8030-ASP |

Power Supply | 380 Volt, 50 Hz |

Installed Power | 32000 Watt |

Average Consumption | 25600 Watt |

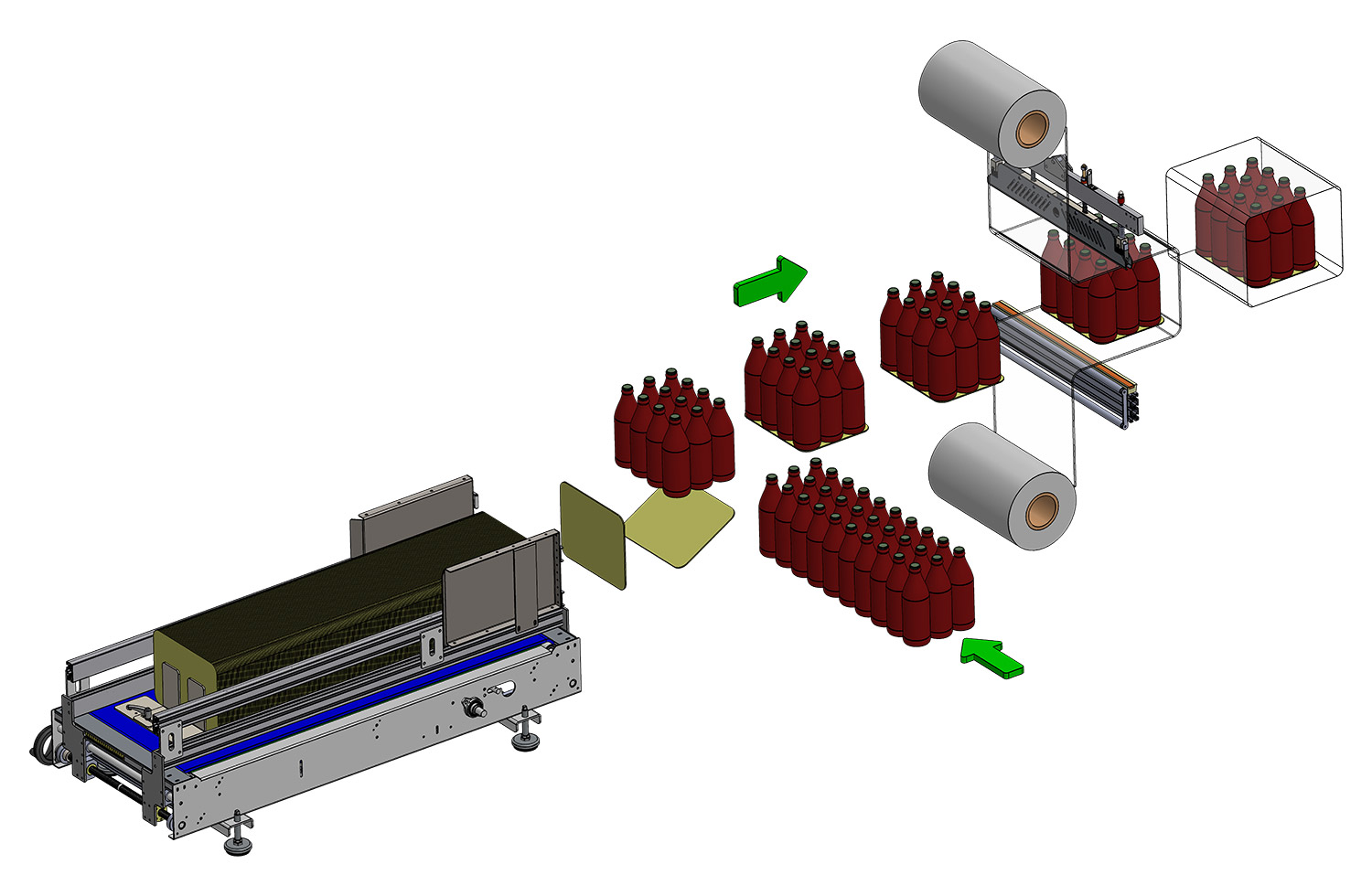

Maximum Product Width | 500 mm |

Maximum Product Height | 380 mm |

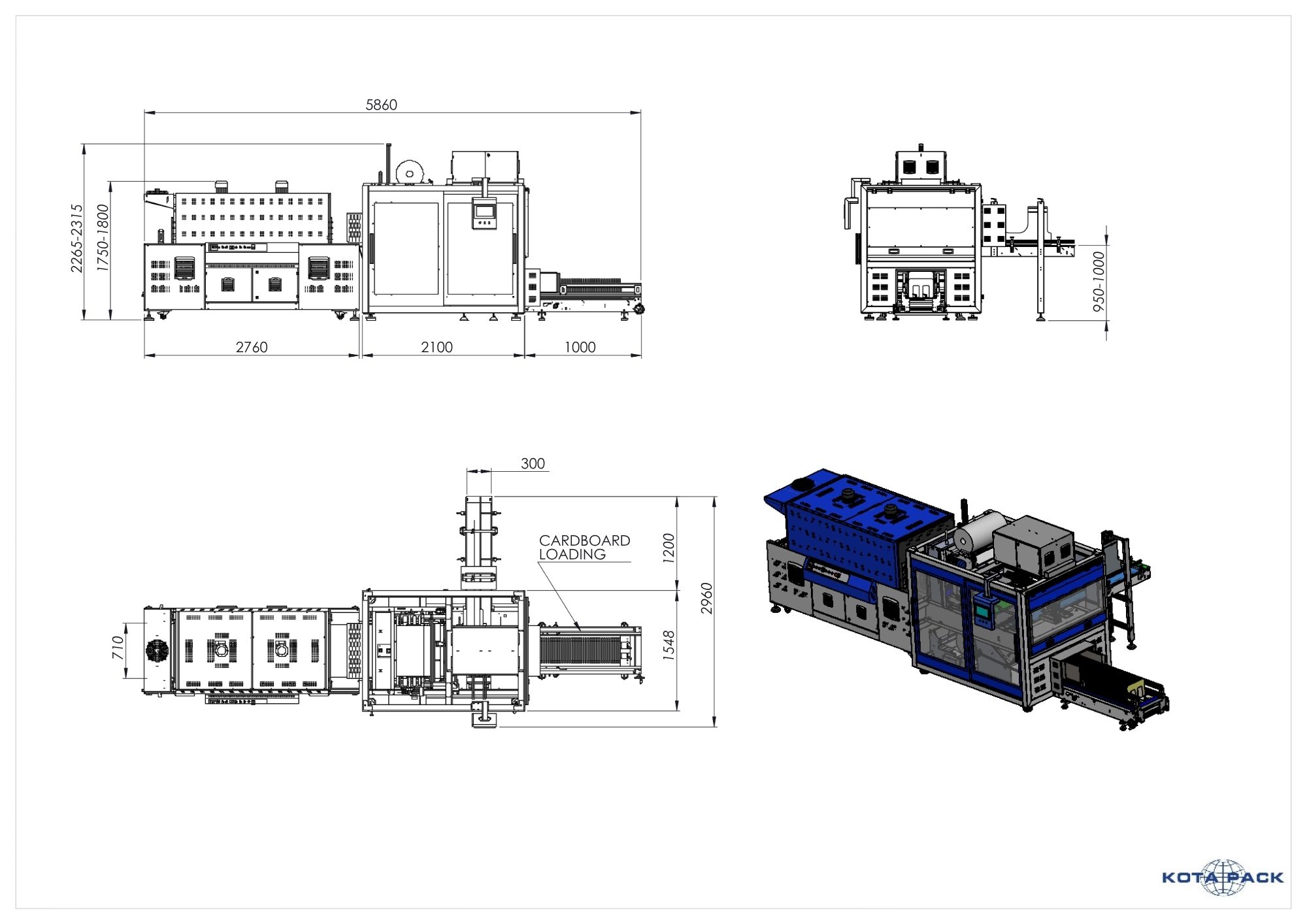

Conveyor Belt Width | 710 mm |

Feeding Conveyor Width | 300 mm |

Tunnel Modular Belt Width | 710 mm |

Sealing Bar Length | 770 mm |

Maximum Film Size | Ø350-750 mm |

Machine Working Height | 950 mm (+50) |

Layout Dimensions (W*L) | 5860 x 2960 |

H 2265 mm (+50) | |

Machine Weight | 1700 Kg |

Usable Films | LDPE: 20-120 µ |

Air Pressure | 6 Bar |

Required Air | 18 Nl/p |

Maximum Capacity | 20 ad/dk |

(*) Packs per minute. The specified capacity may vary depending on the product size, package format, and film type.

.